Do you have a good pump that’s not working as well as it should be? Have you found yourself looking for general pump maintenance information? If so, you’ve come to the right place.

Here, we’ll explore the ins and outs of well pump maintenance and what you need to be aware of when it comes to keeping your pump up and running at its best.

Let’s get started!

Properly Draining and Filling Your Pump

Pump maintenance is essential for the proper functioning of any pump. Properly draining and filling your pump is an important part of this maintenance.

When draining, it is important to first turn off the power supply and identify the drain plug on the pump. Once this is done, a wrench can be used to loosen the drain plug and allow the contained fluid to escape.

After draining, the pump must be refilled with the correct fluid. This fluid should be checked for any contamination and replaced if necessary. The new fluid must then be added to the pump slowly and in the correct quantity.

It should be slowly poured into the inlet side of the pump, and the level monitored until it has reached the correct level. Pump maintenance is important for proper functioning and must be completed correctly for a well-performing pump.

Common Pump Troubleshooting Tips

Pump maintenance common pump troubleshooting tips include regularly checking for faulty parts, such as the impeller, seal, and motor bearings.

Checking for leaks on the seals of the pump. Inspecting the inlet filter for any debris or obstructions. Make sure the impeller is not excessively worn. Disassemble and clean the pump as necessary. Lubricate the motor and all other rotating parts.

Check to make sure proper voltage is being supplied to the motor. If the pump is being used with a pump controller, check the switch sensitivity and adjust it accordingly.

If the pump is used with an automatic control system, inspect the valves and the pressure gauge. Overall, these are just a few tips from the common pump maintenance guide.

How to Keep Your Pump Up and Running

When it comes to pumping maintenance, it’s important to know some of the basics in order to keep your pump up and running. First, you should regularly inspect and lubricate the moving parts of your pump.

This will help to ensure that the pump is running properly and that it is effectively transferring liquid from one area to another. Secondly, you should check the pressure regulator of the pump as well to make sure that it is properly calibrated.

This will help to ensure that the pressure is typically maintained in the system and that it is not too high or too low. Lastly, you should always check to make sure the impeller is in good working order, as this is what helps the pump transfer liquids.

You may also contact the experts at this link: https://www.houghton-international.com/service/pumps/. This way, your pump will be running smoothly and efficiently for years to come!

Identifying and Replacing Worn-Out Parts

To identify worn-out parts, pump operators must inspect the equipment for any signs of damage or wear. Common signs of wear include rust, damage to seals and other parts, and unusual noises from the pump or its associated components.

Once worn parts are usually identified, the pump can be shut down and the worn-out parts removed to be replaced. It is important for the operator to install new, quality parts to ensure the pump continues to work efficiently.

Additionally, the renewed part should be generally checked for correct installation and to make sure it is compatible with the existing system. Failure to address worn parts can lead to costly breakdowns, decreased efficiency, and potentially hazardous situations.

Regular maintenance and timely replacement of worn-out parts are integral aspects of pump upkeep and ensure the system can properly operate.

Knowing When to Call an Expert for Help

Knowing when to call an expert for help is one of the most important steps in preventative maintenance. If the pump isn’t running correctly, it is important to immediately seek assistance from a qualified expert.

Common signs that a pump may need professional help include strange noises, strange smells, and a decrease in efficiency or performance.

Vibrations, leaks, and increases in temperature can also indicate a problem. In addition, pumps that are not properly maintained can suffer increased wear and tear and a decreased lifespan than pumps that are properly cared for.

If you experience any of these symptoms with your pump, it’s best to call an expert right away. A professional can assess the problem and determine the best course of action to fix the issue.

Professional pump maintenance can help extend the life of your pump, saving you money and time in the long run.

Different Types of Pump Maintenance

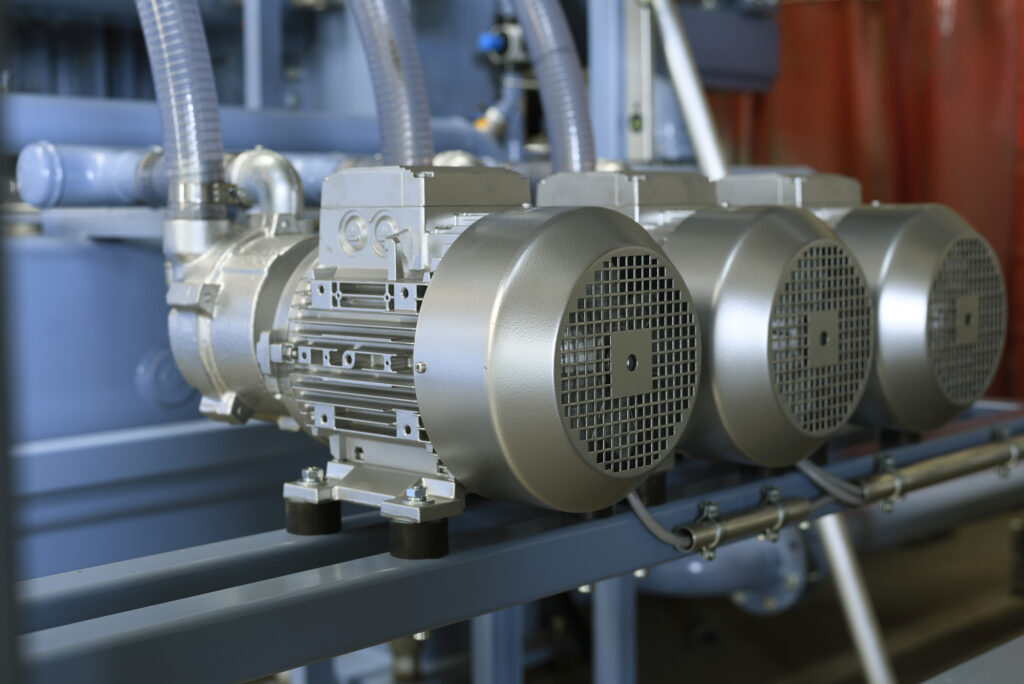

Depending on the type of pump, maintenance requirements will vary. For instance, rotary pumps require regular lubrication to maintain their operation, while reciprocating pumps need periodic oil changes.

Loose components should also be generally checked and replaced in both pump designs. Positive displacement pumps require regular cleaning and inspection of shaft seals and valves, while centrifugal pumps should have their coupling and bearings inspected periodically.

Additionally, all types of pumps may need to be surveyed for vibrations that could indicate a potential issue.

It is important to plan maintenance at regular intervals and document any service that is usually performed; otherwise, pump efficiency and life could be typically compromised. With the right attention, all pumps can enjoy reliable operation for many years.

Always Consider Pump Maintenance

We have seen that pump maintenance is a critical key to getting the most out of our pump operations. Regular maintenance not only extends the lifespan of pumps but also increases energy efficiency and reduces operational costs.

So don’t forget – always consider pump maintenance 101! Schedule regular maintenance to get the most out of your system and your investment.

Did you find this article helpful? Check out the rest of our blogs!